Reactive Acrylic Adhesive

The two-part acrylic adhesive, whose curing properties do not change much even if the mixing ratio and mixing status vary, has user friendliness almost equal to that of one-part adhesive.

Features

- Reactive acrylic adhesive has the robust strength of a structural adhesive.

- Reactive acrylic adhesive is cured quickly.

- Reactive acrylic adhesive contains no inflammable solvent.

- Reactive acrylic adhesive does not have as bad an odor as a conventional acrylic adhesive.

- Reactive acrylic adhesive causes almost no skin irritation. unlike epoxy adhesive.

- The adhesive property of reactive acrylic adhesive is unchanged, even on a slightly oily surface.

Application

- Assembly of building members

- Assembly of signboard

- Assembly of furniture

- Adhesion and assembly of automotive and vehicle parts

- Assembly of magnets

- Assembly of sports goods

Product details

・Multi-purpose type : Y600, Y600H, Y610, Y620

・High heat resistance type : Y611BLACK S, Y612BLACK

・Flexible type : Y618LD, Y618H, Y630D

・Conventional type (*Odorous) : Y650

Product data

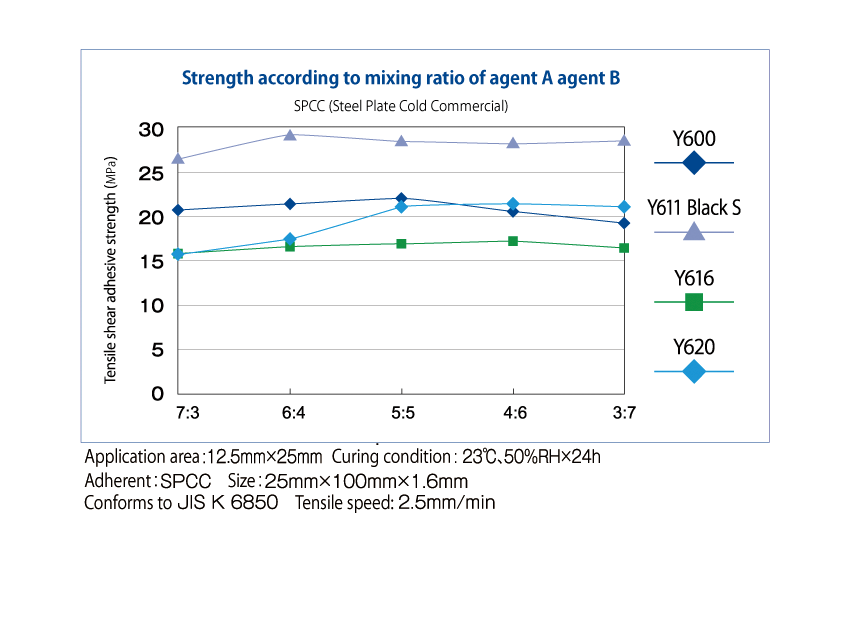

Adhesive strength by mixing ratio

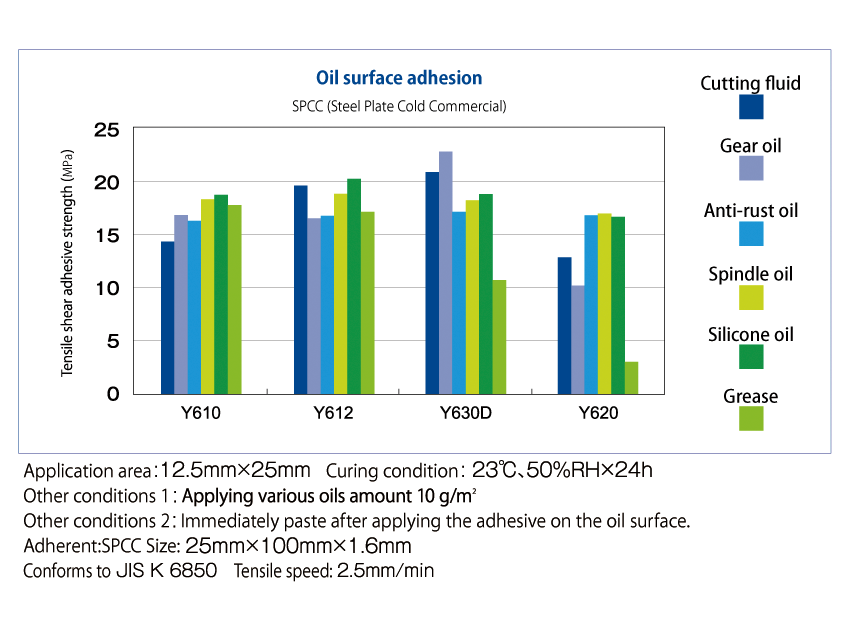

Oil surface adhesion

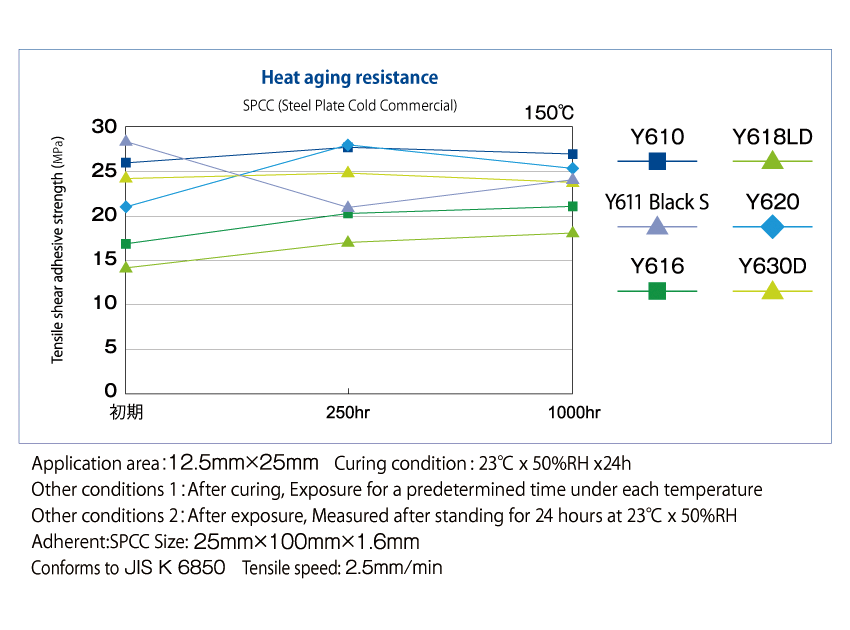

Heat aging resistance

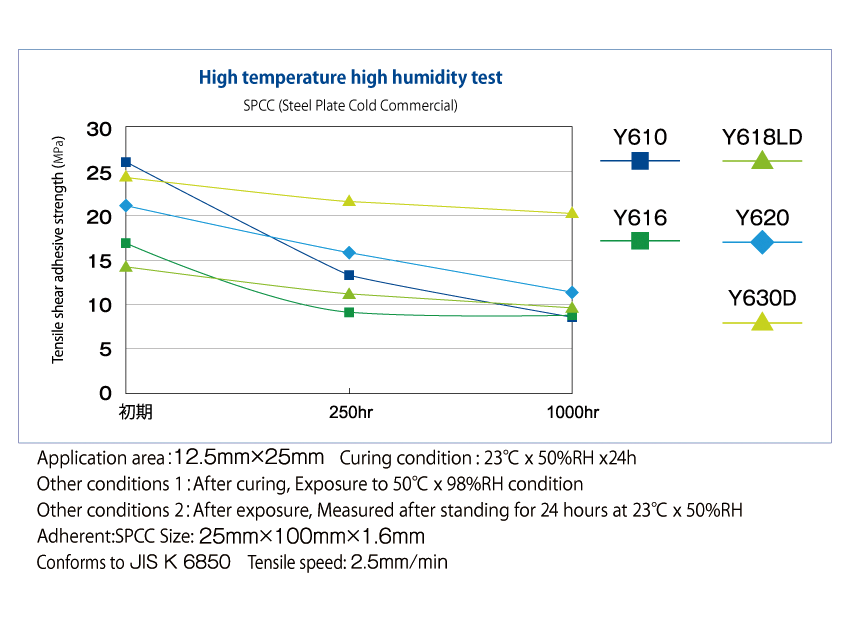

High temperature high humidity durability

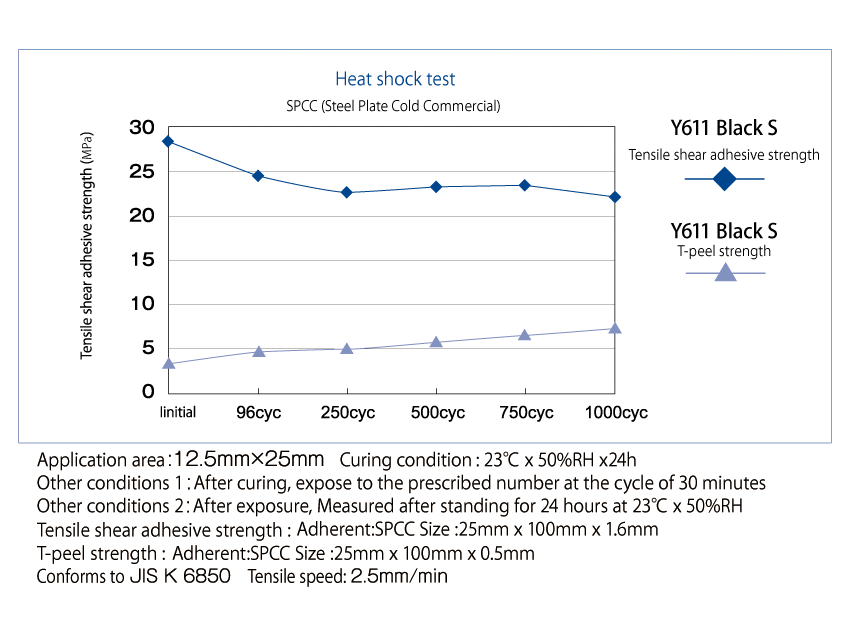

Heat shock testing

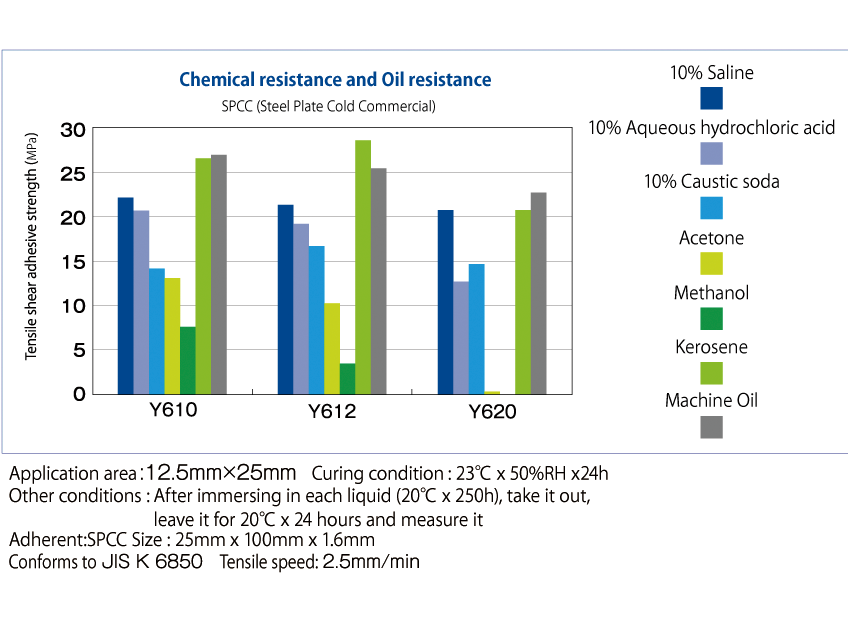

Chemical resistance

Property

Multi-purpose type

| |

Y600 |

Y600H |

Y610 |

Y620 |

| Agent A |

Agent B |

Agent A |

Agent B |

Agent A |

Agent B |

Agent A |

Agent B |

| Application / Properties / Features |

High speed curing |

High viscosity |

High strength |

Slow curing |

| Base |

Acrylic resin |

Acrylic resin |

Acrylic resin |

Acrylic resin |

| External appearance |

Light blue |

Blue |

White |

Gray |

White |

Gray |

Light yellow |

Blue |

| Viscosity |

mPa・s/23°C |

4,000 |

4,000 |

30,000 |

30,000 |

5,500 |

5,500 |

8,000 |

8,000 |

| Mixing ratio |

1:1 |

1:1 |

1:1 |

1:1 |

| Pot life *1 |

23°C |

30 s |

2 min |

3 min |

6 min |

| Set time *2 |

23°C |

3 min |

4 min |

6 min |

20 min |

| Adhesive property |

Tensile shear strength |

MPa |

23.2 |

19.4 |

26.0 |

21.1 |

| T-peel strength |

N/mm |

5.0 |

3.6 |

3.7 |

4.2 |

| Curing properties |

Hardness |

Shore A |

68 |

65 |

72 |

66 |

| Glass transfer point |

°C |

83 |

78 |

90 |

79 |

| Elastic modulus |

MPa |

767 |

742 |

935 |

778 |

| Breaking strength |

MPa |

16.2 |

14.0 |

19.0 |

16.1 |

| Elongation at break |

% |

26 |

8 |

6 |

25 |

| Capacity |

600g set |

50g set |

50g set |

600g set |

| |

10kg |

600g set |

2kg |

| |

|

|

|

| |

|

|

|

|

*1 : After mixing agents A and B, immediately use the mixture to bond the materials (the pot life is an estimate).

*2 : Set time = Time required for the materials to adhere so that they will not peel off even when a tensile shear load of 5 kg is applied (SPCC steel plates with a size of 25 mm×100 mm×1.6 mm bonded with a lap length of 12.5 mm).

High heat resistance type

| |

Y611BLACK S |

Y612BLACK |

| Agent A |

Agent B |

Agent A |

Agent B |

| Application / Properties / Features |

Hight strength / High heat resistance |

| Base |

Acrylic resin |

Acrylic resin |

| External appearance |

Light yellow |

Black |

Light yellow |

Black |

| Viscosity |

Pa・s/23°C |

3,000 |

3,000 |

15,000 |

15,000 |

| Mixing ratio |

1:1 |

1:1 |

| Pot life *1 |

23°C |

3 min |

1 min |

| Set time *2 |

23°C |

7 min |

3 min |

| Adhesive property |

Tensile shear strength |

MPa |

28.4 |

29.2 |

| T-peel strength |

N/mm |

4.2 |

4.3 |

| Curing properties |

Hardness |

Shore D |

84 |

86 |

| Glass transfer point |

°C |

123 |

127 |

| Elastic modulus |

MPa |

1558 |

1615 |

| Breaking strength |

MPa |

32.9 |

33.7 |

| Elongation at break |

% |

3.5 |

3.2 |

| Capacity |

600g set |

600g set |

| 10kg/BIB |

10kg/BIB |

| |

|

|

*1 : After mixing agents A and B, immediately use the mixture to bond the materials (the pot life is an estimate).

*2 : Set time = Time required for the materials to adhere so that they will not peel off even when a tensile shear load of 5 kg is applied (SPCC steel plates with a size of 25 mm×100 mm×1.6 mm bonded with a lap length of 12.5 mm).

Flexible type

| |

Y618LD |

Y618H |

Y630D |

| Agent A |

Agent B |

Agent A |

Agent B |

Agent A |

Agent B |

| Application / Properties / Features |

Flexible / Low distortion |

Hight strength / High heat resistance |

| Base |

Acrylic resin |

Acrylic resin |

Acrylic resin |

| External appearance |

Red |

Blue |

Light yellow |

Light green |

Light yellow |

Light green |

| Viscosity |

Pa・s/23°C |

5,000 |

5,000 |

15,000 |

15,000 |

4,000 |

4,000 |

| Mixing ratio |

1:1 |

1:1 |

1:1 |

| Pot life *1 |

23°C |

2 min |

2 min 30 s |

1 min 30 s |

| Set time *2 |

23°C |

7 min |

10 min |

4 min 30 s |

| Adhesive property |

Tensile shear strength |

MPa |

14.2 |

15.7 |

25.3 |

| T-peel strength |

N/mm |

5.9 |

5 |

4.6 |

| Curing properties |

Hardness |

Shore D |

47 |

55 |

83 |

| Glass transfer point |

°C |

61 |

|

118 |

| Elastic modulus |

MPa |

451 |

|

2414 |

| Breaking strength |

MPa |

10.5 |

10.6 |

32.1 |

| Elongation at break |

% |

40 |

51 |

2 |

| Capacity |

600g set |

190mL set |

600g set |

| 10kg/BIB |

|

|

| |

|

|

|

*1 : After mixing agents A and B, immediately use the mixture to bond the materials (the pot life is an estimate).

*2 : Set time = Time required for the materials to adhere so that they will not peel off even when a tensile shear load of 5 kg is applied (SPCC steel plates with a size of 25 mm×100 mm×1.6 mm bonded with a lap length of 12.5 mm).

Conventional type SGA Y650 (*Odorous)

| |

Y650 |

| Agent A |

Agent B |

| Base |

Acrylic resin |

| External appearance |

Blue |

Red |

| Viscosity |

mPa・s/23°C |

3,220 |

3,320 |

| Mixing ratio |

1:1 |

| Pot life *1 |

23°C |

2 min 30 s |

| Set time *2 |

23°C |

4 min 30 s |

| Adhesive property |

Tensile shear strength |

MPa |

23.8 |

| T-peel strength |

N/mm |

4.6 |

| Curing properties |

Hardness |

Shore D |

60 |

| Glass transfer point |

°C |

83 |

| Elastic modulus |

MPa |

740 |

| Breaking strength |

MPa |

16.1 |

| Elongation at break |

% |

25 |

| Capacity |

2.5kg |

*1 : After mixing agents A and B, immediately use the mixture to bond the materials (the pot life is an estimate).

*2 : Set time = Time required for the materials to adhere so that they will not peel off even when a tensile shear load of 5 kg is applied (SPCC steel plates with a size of 25 mm×100 mm×1.6 mm bonded with a lap length of 12.5 mm).