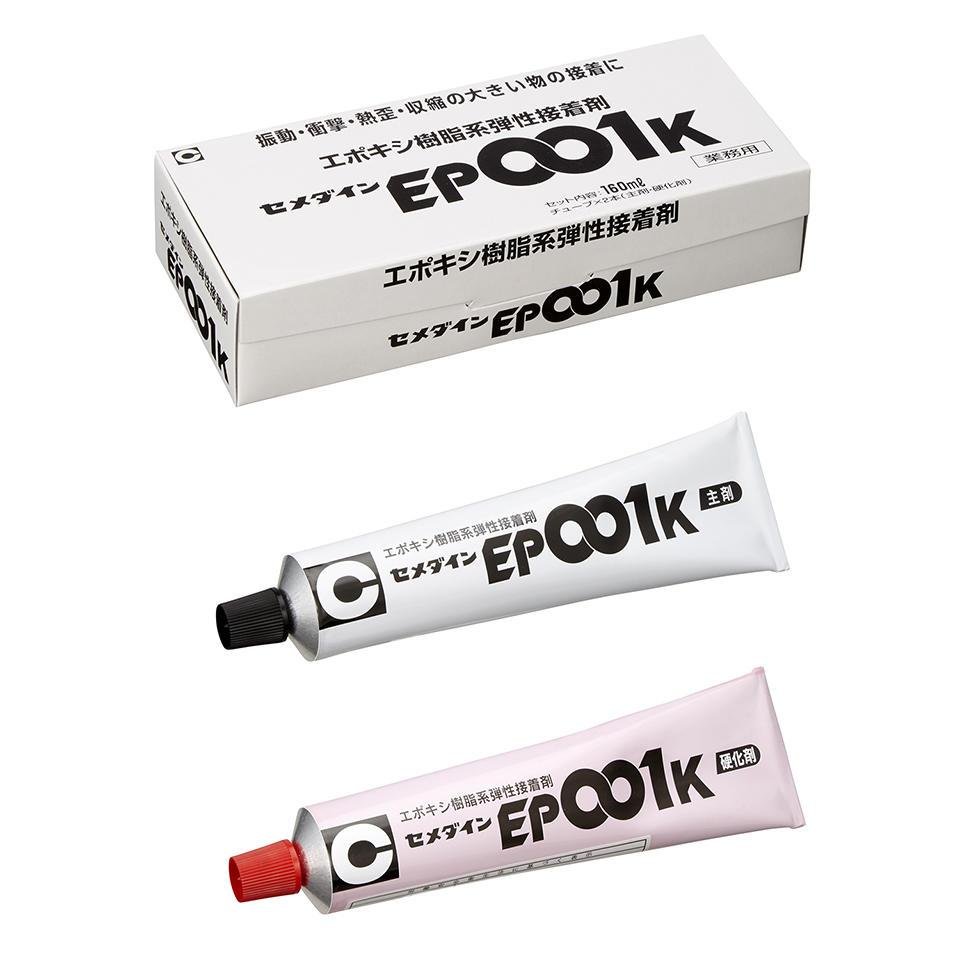

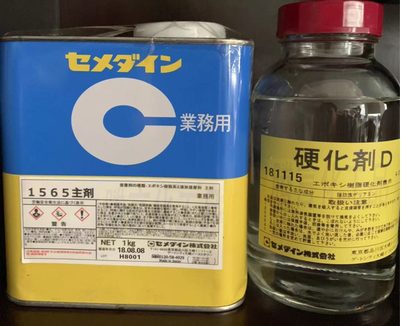

Model No.︰EP001K

Brand Name︰Cemedine

Country of Origin︰Japan

Unit Price︰CNY ¥ 85 / pc

Minimum Order︰10 pc

Epoxy Resin AdhesiveEpoxy/silyl terminated polyether elastic adhesive

Features

Application

Product data

Adhesive properties for various types of adherends

(MPa)

| Tensile shear strength | Failure Modes | ||

|---|---|---|---|

| Plastic | PVC | 5.51 | CF |

| PC | 5.46 | CF | |

| ABS | 5.38 | CF | |

| PMMA | 3.72 | CF2AF8 | |

| 6Ny | 4.07 | CF8AF2 | |

| PET | 4.88 | MF | |

| PBT | 3.44 | AF | |

| PPO | 4.16 | CF5AF5 | |

| PPS | 4.19 | CF5AF5 | |

| Metal | SPCC | 6.15 | CF |

| AL | 7.57 | CF7AF3 | |

| SUS | 5.90 | CF8AF2 | |

*CF:Cohesion Failure, AF:Adhesive Failure, TCF:Thin layer cohesion failure, MF:Failure Modes

The numbers indicate their proportion to the adhesion area.

Test method : JIS K6850

Curing: 23°C50%RH×7 days

Characteristics by mixing ratio

| Mixing ratio

(Base resin : Hardener) |

Tensile shear strength | Peeling strength | Hardness

(Shore A) |

||

|---|---|---|---|---|---|

| Adhesion strength | Failure Modes | Adhesion strength | Failure Modes | ||

| 60 : 40 | 6.04 MPa | CF | 2.90 N/mm | CF | 75 |

| 55 : 45 | 6.15 MPa | CF | 3.14 N/mm | CF | 72 |

| 50 : 50 | 6.15 MPa | CF | 3.85 N/mm | CF | 72 |

| 45 : 55 | 7.10 MPa | CF | 4.12 N/mm | CF | 71 |

| 40 : 60 | 6.09 MPa | CF | 3.90 N/mm | CF | 69 |

*CF:Cohesion Failure

Test method: JIS K6850

Adherends: Steel plate

Surface treatment: Degreased with MEK

Curing: 23°C50%RH×7 days

Heat aging test

(MPa)

| Test conditions

(temperature×time) |

Tensile shear strength | ||

|---|---|---|---|

| Initial value | 6.15 | CF | |

| 100°C | 500h | 7.56 | CF |

| 1000h | 7.53 | CF | |

| 120°C | 100h | 6.11 | CF |

| 250h | 5.38 | CF | |

| 500h | 4.61 | CF | |

| 1000h | 2.59 | CF | |

| 150°C | 100h | 6.15 | CF |

| 250h | 3.10 | CF | |

| 500h | 3.08 | CF | |

| 1000h | 2.68 | CF | |

| 180°C | 100h | 2.10 | CF |

| 250h | 1.20 | AF | |

*CF:Cohesion Failure,AF:Adhesive Failure

Test method : JIS K6850

Adherends: Steel plate

Surface treatment: Degreased with MEK

Tension speed: 50 mm/min

Tensile shear strength on each temp

(MPa)

| Adhesion strength | Failure Modes | |

|---|---|---|

| -40°C | 8.96 | CF |

| 23°C | 6.15 | CF |

| 50°C | 5.95 | CF |

| 80°C | 6.27 | CF |

| 100°C | 6.13 | CF |

| 120°C | 2.83 | CF3AF7 |

| 150°C | 2.64 | CF2AF8 |

*CF:Cohesion Failure

Test method : JIS K6850

Adherends: Steel plate

Surface treatment: Degreased with MEK

Tension speed: 50 mm/min

High-temperature and high-humidity test

(MPa)

| Adhesion strength | Failure Modes | ||

|---|---|---|---|

| Initial value | 7.57 | CF | |

| 85°C85% | 100h | 8.96 | CF |

| 250h | 7.83 | CF | |

| 500h | 7.14 | CF | |

| 1000h | 6.81 | CF | |

*CF:Cohesion Failure

Test method : JIS K6850

Adherends: Aluminum

Property

| EP001K | ||||

|---|---|---|---|---|

| Base resin | Hardener | |||

| Application / Properties / Features | Elasticity | |||

| Type | Two-part epoxy adhesive curing at room temperature | |||

| Base | Epoxy resin | Silyl terminated polyether | ||

| Appearance | Milky white | Light yellow | ||

| Non-volatiles | wt% | 99 | 97 | |

| Viscosity | Pa・s/23°C | 14 | 18 | |

| Density | g/cm3 | 1.15 | 1.00 | |

| Standard curing conditions | 23°C×7days | |||

| 23°C 3days+50°C 3days | ||||

| Mixing ratio | 1 : 1 | |||

| Pot life | 23°C | 11 min. | ||

| Set time | 23°C | 40 min. | ||

| Time required for effective curing | 23°C | 24 hours | ||

| Cured properties | Hardness | Shore A | 72 | |

| Glass transition temperature | °C | -65 | ||

| Elastic modulus | MPa | 3.2 | ||

| Breaking strength | MPa | 6.7 | ||

| Elongation at break | % | 200 | ||

| Water absorption ratio | % | 1.8 | ||

| Linear expansion coefficient | 15×10-5 | |||

| Capacity | 320ml set | |||

| 2kg set | ||||

Price Terms︰ FOB HONGKONG, FOB SHENZHEN

Payment Terms︰ TT